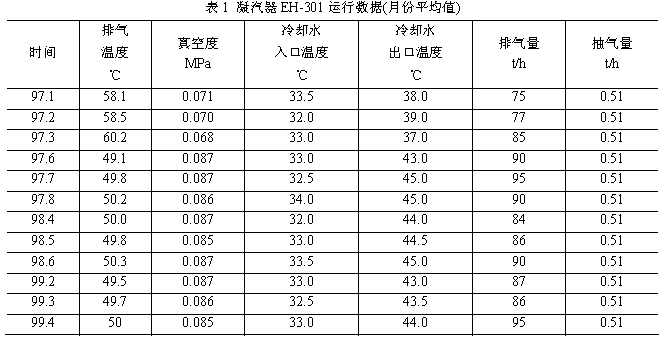

(1)循环水出口温度升高。该厂凝汽器入口循环水采用二级水,温度一直控制在31℃~34℃之间。1997 年6 月份防垢器安装后,凝汽器出水温度一直保持在43℃以上,比防垢器投用前提高了5℃左右,循环水吸热量增加。凝汽温度与冷却水出口的传热温差降低。

(2)透平排汽温度降低,真空度上升。防垢器安装后,透平真空度一直维持在0.085~0.087MPa范围内,与安装前相比,抽汽量不变,尽管透平排汽量增大,但排气温度平均下降了10℃,真空度上升了0.015MPa。

4. 结语

超声波除垢具有既能防止积垢的形成,又能破坏已有积垢的双重作用。超声技术在石油化工等领域中的成功运用,可提高产品质量,保障生产和设备的安全运行,降低成本,提高生产效率[8]。超声波防除积垢技术操作简单、成本低,是今后电力行业防除积垢技术的发展方向。

参考文献

[1]. Collier J G.Heat Exchanger Fouling and Corrosion[C].In Heat Exchanger: Thermal-Hydraulic Fundamentalsand Design(Kakac S, Bergles AE and Mayinger F,eds.),Hemisphere, Washington, D.C.1981:999-1011.

[2]. 李淑琴,程永清.声化学法除垢研究[J].陕西化工,1997,(9):22-23.

[3]. 念保义,陈金平.超声波抑制积垢的影响因素与机理的研究[J].天津化工,2001,(5):10-12.

[4]. 罗宪中,李贵平,翁良华. 超声波领域新拓展—超声防垢[J].清洗世界,2004,(06):52-55.

[5]. Cloke J B, Knowles E C, Anderson R J. Ethyl in irlocy-clopropanecarboxy late hydrochloride [J]. TheJournal of the American Chemical Society, 1936, 58:2547-2549.

[6]. 李雅莉.超声波清洗的原理与实际应用[J].清洗世界,2006,(07):31-35.

[7]. 赵国华,姜峰,李修伦.超声波技术在制盐工业中的应用前景[J].海湖盐与化工,2004,33(5):34-36.

[8]. 胡爱军,黄运贤,丘泰球等.超声波防除积垢节能技术及设备的工业化应用[J].应用化工,2001,30(5):37-40.

Application of Ultrasonic Scaling in the Power Plant

ZHANG Wenyong, XU Hong

Department of Energy and Power Engineering, North China Electric Power University, Beijing,102206

Abstract

In this paper, starting from the point “energy-saving and cost-reducing”, an overview of the seriousnessand the economic losses caused by power plant fouling are carried out. The paper investigates themechanism and the benefits of ultrasonic used in cleaning fouling, as well as its application in powerplant heat exchangers. It is possible to come to the conclusions that ultrasonic cleaning is the rightdirection of cleaning fouling technology development in the future, but also fouling control technologyin power industry.

Keywords: ultrasonic; scaling; heat exchanger; application

空气耦合式超声波无损检测技术的

06-08

空气耦合式超声波无损检测技术的

06-08

超声波测距系统

04-15

超声波测距系统

04-15

超声波声速测量新方法

06-05

超声波声速测量新方法

06-05

超声波探伤实验

09-24

超声波探伤实验

09-24

超声波测距仪研究

06-03

超声波测距仪研究

06-03

超声波在悬浮液中的衰减

06-09

超声波在悬浮液中的衰减

06-09